Rugged Multi-Environment

Analysis Device

A deployable environmental monitoring device designed to collect critical sensor data in remote or hazardous areas — dropped from an aircraft, slowed by parachute, and landed on foam-dampened telescoping legs. Data transmitted wirelessly over RF to keep operators at a safe distance.

Context

The Problem

Unexplored locations, disaster sites, and remote environments can threaten anyone attempting to assess whether an area is safe for human habitation. Current solutions have gaps: fixed Environmental Monitoring Stations require existing infrastructure, and UAVs are limited by short deployment time, high cost, and the need for trained operators.

The team set out to build a device that could fill those gaps — something inexpensive, infrastructure-independent, and capable of long-term deployment in areas where neither fixed stations nor drones can operate.

Solution

The Device

RMEAD is a self-contained sensing payload designed to be deployed as a drop from a manned or uncrewed aircraft. A 49-inch parachute slows its descent; three foam-dampened telescoping legs absorb the landing impact. Once stationary, onboard sensors collect temperature, humidity, pressure, gas/VOC indicators, and ambient light levels, transmitting readings over 433 MHz RF to a nearby receiver — keeping operators at a safe distance.

The device's simple and inexpensive deployment system allows it to be stationed in remote environments with rugged terrain, providing accurate, long-term monitoring with the advantage of versatile placement. Unlike UAVs, it doesn't require a trained operating team or constant power-hungry flight. Unlike fixed monitoring stations, it doesn't need pre-existing infrastructure.

Its simplicity also opens the door for scaling: larger versions could hold a wider range of sensors or extend operational time with bigger batteries — a problematic venture for current solutions. The team also explored concepts for hydraulic suspension systems for ground deployment and flotation devices for maritime use.

Technical

System Architecture

ENV Pro Unit (BME688)

Temperature, humidity, air pressure, gas resistance (VOC detection), and relative altitude. The BOSCH BME688 sensor covers all atmospheric data requirements in a single module.

Ambient Light Sensor

DFRobot 0–200,000 lux sensor with IR/UV blocking. Range exceeds typical outdoor conditions (~100k lux), enabling detection of hazardous light levels beyond direct sunlight.

RF Communication

DFRobot APC220 module operating at 433 MHz with a quoted 1000–1200m line-of-sight range. Infrastructure-independent, low power, and received via USB-to-TTL converter on a laptop running SerialPlot.

Parachute System

49-inch solid canopy parachute sized using model rocketry calculations for the ~3 lb payload. Slows descent to a survivable impact speed for the landing mechanism below.

Landing Legs

Three telescoping legs with three-layer foam damping in a triangular layout. Original spring design was abandoned after testing showed excessive rebound and tip-over risk. Lubricated with WD-40 Specialist Silicone for smooth compression.

Body & Assembly

3D-printed body assembled with J-B Weld PlasticBonder and finished with heat-resistant radiator spray paint. Materials chosen for durability in adverse conditions.

Design

Landing System Evolution

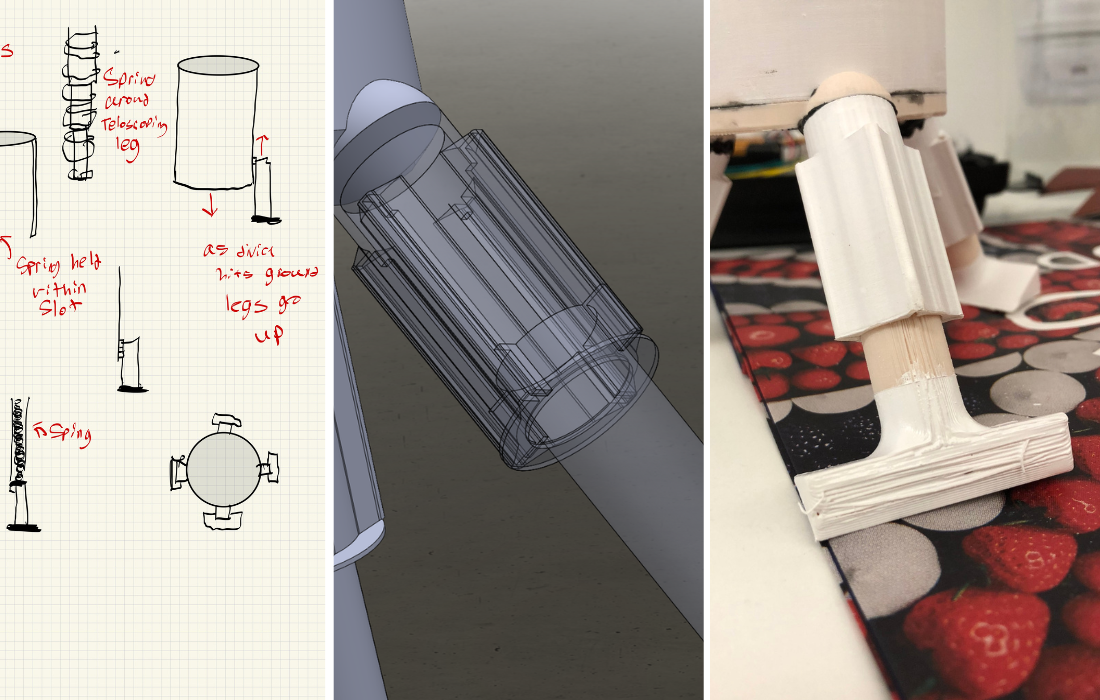

Inspired by Mars landers like InSight, the landing system went through several design iterations. Initial napkin sketches explored both exterior and interior spring configurations for the telescoping legs. The springs were prototyped and tested, but impact testing revealed a critical flaw: the rebound from springs on impact caused the device to tip over.

After testing four different foam types at varying ratios and volumes, the team settled on a three-layer solution that maximized impact absorption without excessive rebound. The final legs used sanded inner surfaces and silicone lubricant to ensure smooth, consistent compression on landing.

See It In Action

Foam-dampened leg compression test — three-layer foam absorbs impact without rebound

Communication

Why RF?

The team evaluated Bluetooth, cellular, Wi-Fi, and RF for the data link. RF won on every criterion that mattered for the use case: long range without infrastructure, low power consumption at moderate distances, and complete independence from networks outside the team's control.

The APC220 module operates at 433 MHz — a legally accepted band in the UK where the device was developed and tested. A USB-to-TTL converter on the receiving end feeds data to a laptop running SerialPlot for real-time visualization. Testing confirmed reliable transmission at moderate range, though shorter than the manufacturer's 1000m quote at the 5V power level used.

See It In Action

Live sensor data streaming wirelessly to a laptop via 433 MHz RF

Engineering

Key Decisions

Contributions

My Role

Concept & Mechanical Design

Created initial device concepts (from napkin sketches to SolidWorks models), designed the telescoping leg mechanism, and iterated CAD for 3D printing constraints. Led the physical design evolution from exterior springs to the final foam-dampened system.

Embedded Software & RF Pipeline

Developed the embedded code for sensor data collection and RF transmission. Built and tested the full data pipeline from sensor reading through APC220 transmission to laptop-side reception and real-time plotting via SerialPlot.

Hardware Selection & Integration

Researched, sourced, and validated all sensors and the RF communication system. Wired and tested prototypes, soldered connections, and assembled the final device. Managed component procurement within the $100 team budget.

Testing & Documentation

Conducted parachute deployment tests, landing impact tests across four foam types, and RF range testing. Authored the design project report including technical documentation with 57 cited references and an ethical analysis of environmental monitoring equity.

Results

Outcome

The team delivered a functioning prototype that demonstrated live sensor readout and wireless data transmission. The parachute and foam landing system performed as designed in drop tests — including a test off the side of Tower Bridge.

Beyond the prototype, the team identified clear scaling paths: larger-scale versions with wider sensor arrays and bigger batteries, hydraulic suspension for ground deployment, and flotation devices for maritime use. The device's simplicity and low cost make these extensions feasible in ways that are problematic for existing UAV-based or fixed-station solutions.

Documentation

Design Report

The full individual design project report — covering technical design, sensor selection, RF communication, landing system development, ethical analysis, and 57 cited references.