Autonomous

Maze-Solving Robot

A semester-long build progressing through four challenges — from driving in a straight line to solving unknown mazes with 45-degree walls. Two people, one SparkFun kit, and a lot of debugging.

Overview

The Project

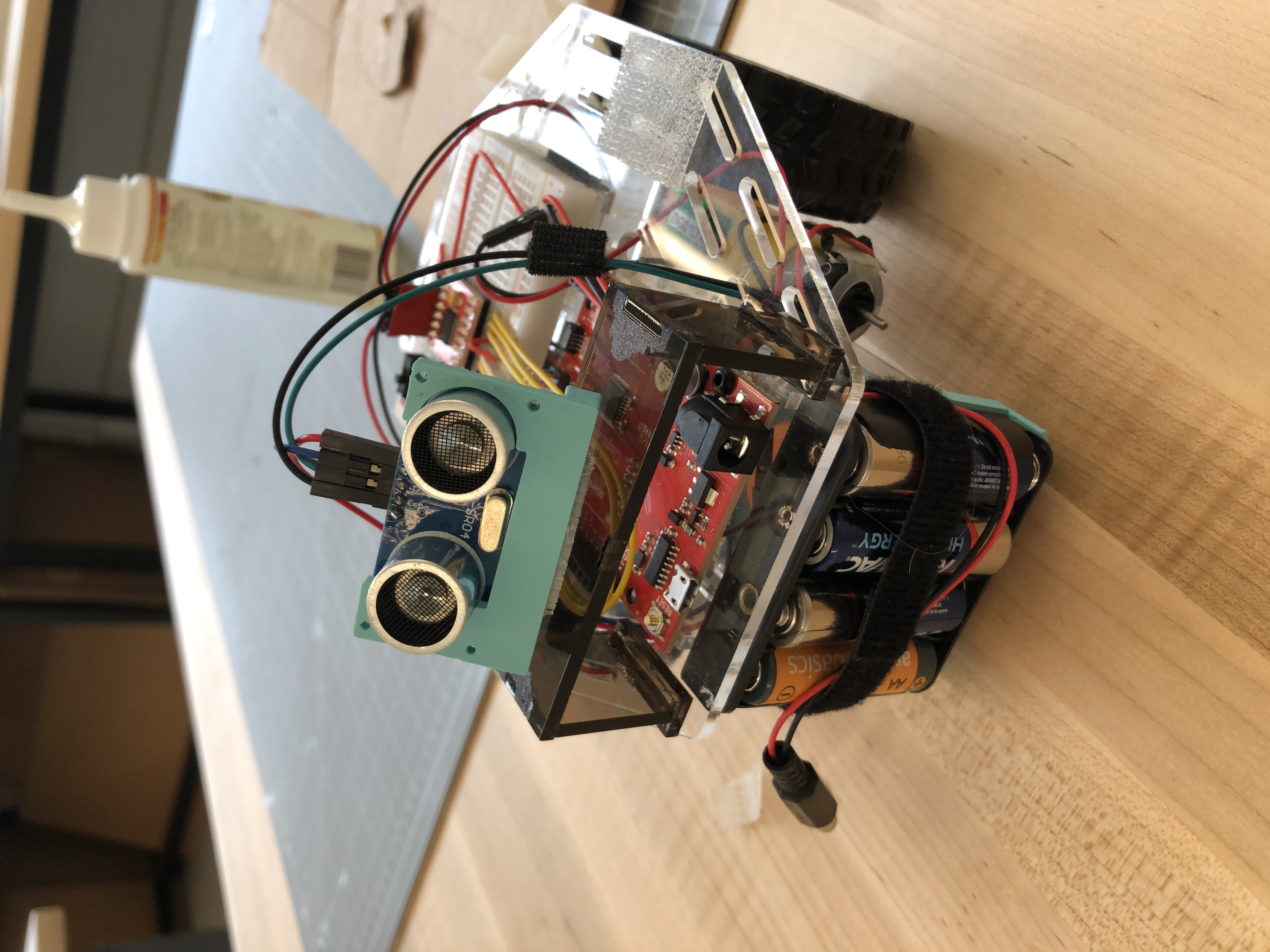

The final project of Cornerstone of Engineering One challenged two-person teams to build an autonomous robot from a SparkFun Inventor's Kit — a RedBoard, breadboard, motor driver, two DC motors, and an ultrasonic sensor — and navigate it through four progressively harder challenges.

Each challenge built on the last: straight-line driving, route navigation with turns, sensor-based obstacle avoidance, and full autonomous maze solving. The project tested technical skill, systematic debugging, and the ability to make engineering tradeoffs under time pressure.

Progression

Four Challenges

Drive in a Straight Line — 4 Feet

The seemingly simple task of driving four feet revealed that the left motor was significantly more powerful than the right, causing the robot to veer off course. After testing and calibrating individual motor speeds, the team achieved consistent straight-line movement.

Navigate a Preset Route

The robot had to follow a specific path with both right and left turns. Moving from a clean wood surface to the maker space's cold concrete introduced unpredictable traction — the robot drifted left on one run and right on the next. The fix combined cleaning wheels before each attempt, lowering overall speed, and fine-tuning turn angles.

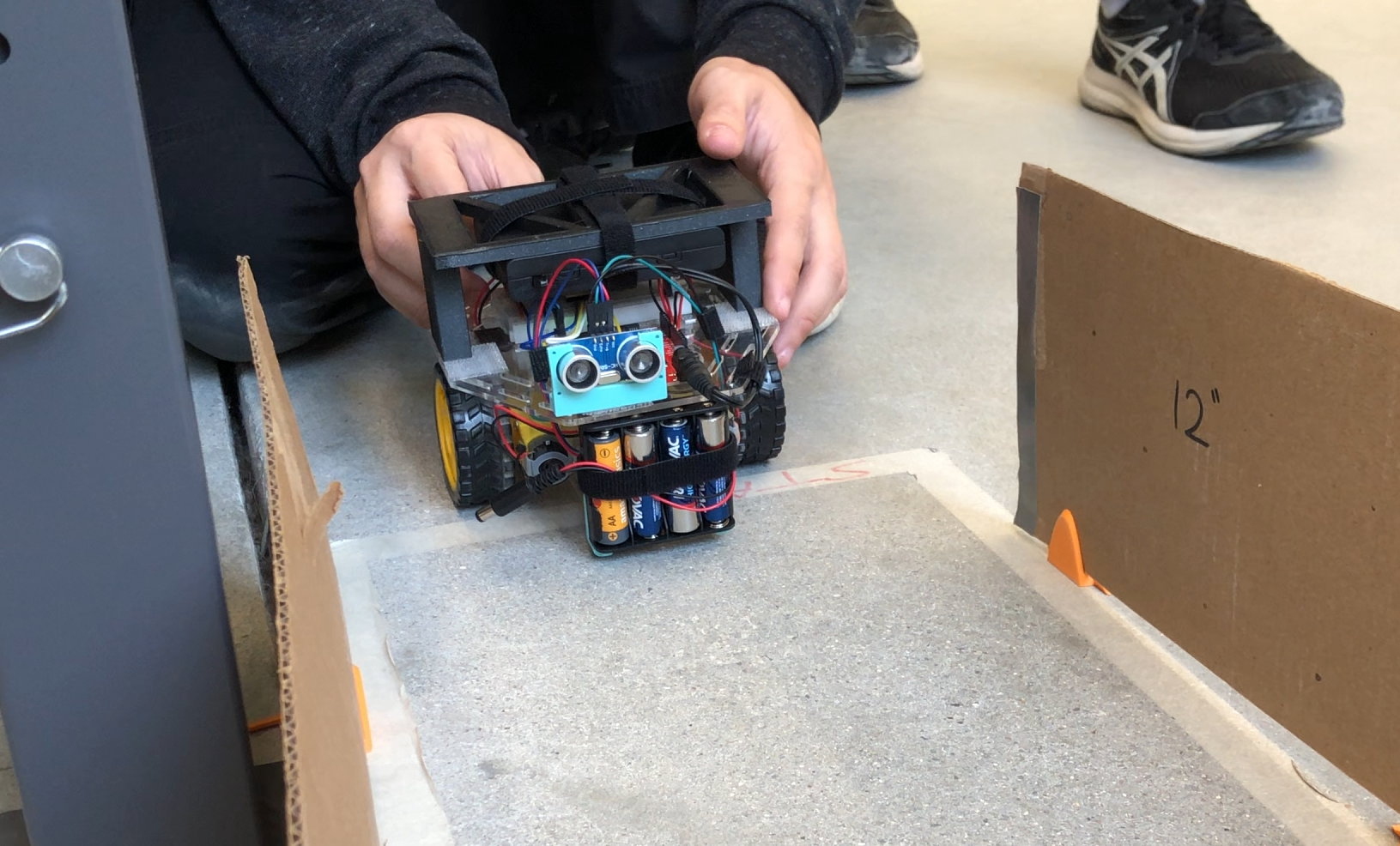

Autonomous Obstacle Detection

The robot needed to detect blocked paths with an ultrasonic sensor and decide whether to turn or stop. The logic used nested conditionals inside a while loop: drive forward until an obstacle is detected, check left, check right, continue or halt.

This challenge triggered the project's biggest crisis. The robot worked on USB power but failed on battery — spinning erratically instead of following its program. After a 5+ hour debugging session including a complete rewire, motor swaps, and single-motor isolation tests, the root cause emerged: the 4-cell battery pack couldn't supply enough current to power both motors and the sensor simultaneously. A 6-cell pack with a custom 3D-printed mount resolved it.

Autonomous Maze Navigation

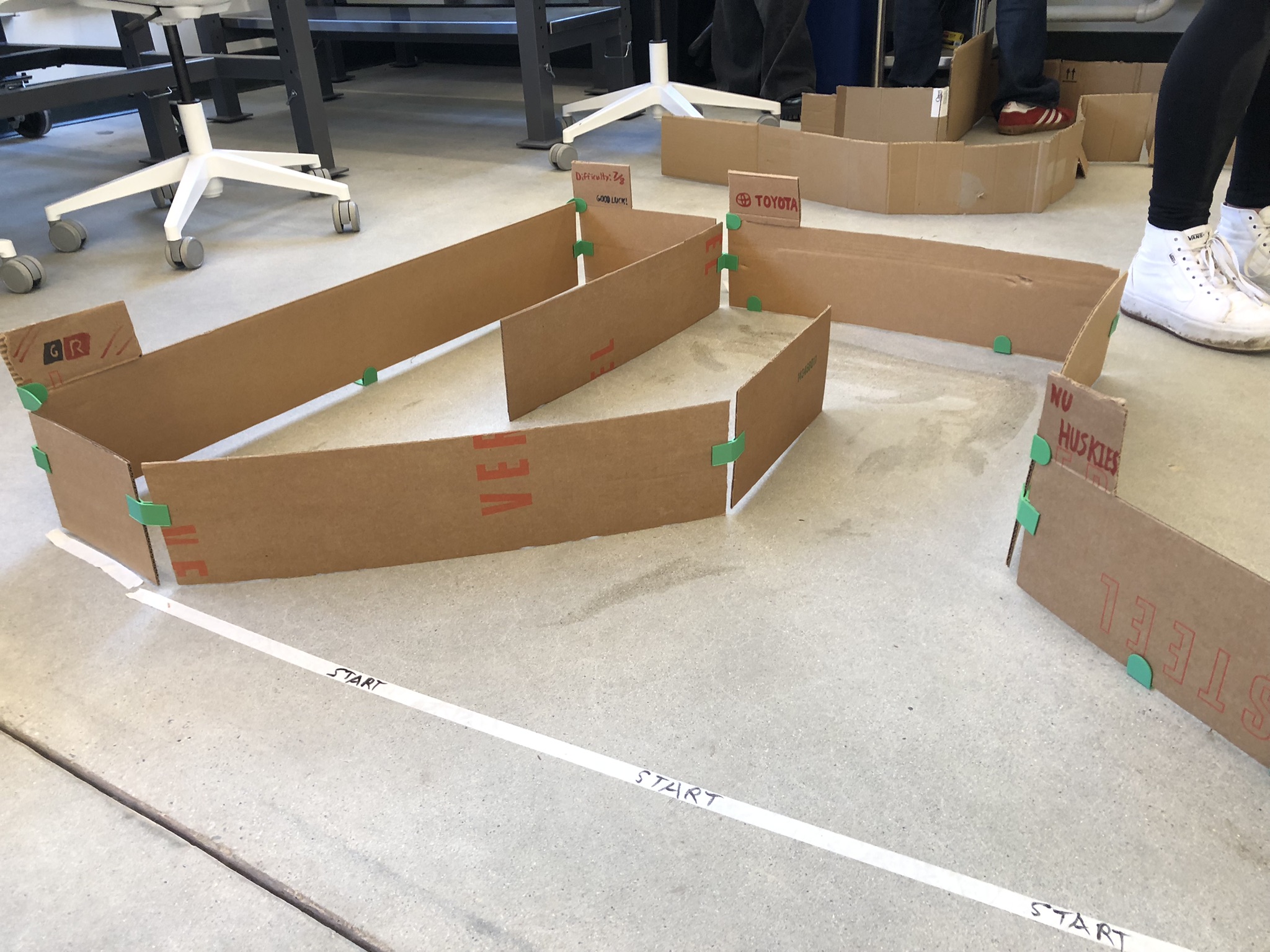

The final challenge: navigate three unknown mazes. The team designed a modular maze with 45-degree angled walls — earning a difficulty score of 7/8, among the hardest in the class. This forced a complete code rewrite: instead of only checking 90-degree turns, the robot scanned all four directions at each wall, measured distances, and chose the farthest open path.

Cardboard walls were cut to precise AutoCAD dimensions and connected with 3D-printed stands. The team scored 3/5 on each of the three mazes, losing points to minor redirections and wall collisions.

The Rewire

Debugging the Power Crisis

When the robot worked on USB but failed on battery, the team systematically ruled out every possibility: new jumper wires, verified placements against the reference diagram, different laptops and cables, new motors, and single-motor isolation.

The breakthrough came when a classmate mentioned that some teams fixed similar issues by switching to a 6-cell battery pack. The 4-cell pack was delivering enough power for the motors alone but couldn't simultaneously drive the ultrasonic sensor — causing erratic readings that sent the robot spinning.

The rewire used hookup wire with planned, parallel routing that made the system readable at a glance and fast to troubleshoot.

Design

Sensor Mount Solution

The team's reverse-drive configuration placed the powered wheels at the rear and the ping pong ball caster at the front — better for turning, but it put the ultrasonic sensor directly over the RedBoard's power and USB ports.

Three mounting solutions were evaluated using Kepner-Tregoe Decision Analysis: a side mount, a front mount, and a riser bracket. The riser scored highest for feasibility, risk, and impact. It was designed in AutoCAD, laser cut, and assembled with adhesive — giving the sensor a clear line of sight while preserving access to all ports below.

Challenge 4

The 45° Maze

The team intentionally designed the hardest maze possible, introducing 45-degree angled walls that no other team had attempted. Walls were cut from cardboard to AutoCAD specifications with at least 10 inches of clearance throughout, and connected using custom 3D-printed stands.

The unconventional angles forced a full rewrite of the navigation algorithm — and the resulting code generalized to handle any maze configuration the robot encountered on demo day.

Contributions

My Role

Assembly & Wiring

Owned all physical assembly and wiring from the first build session. Designed clean, parallel wire runs using planned routing and measured lengths — making the system readable at a glance and quick to debug. Performed a full rewire during the Challenge 3 power crisis, systematically isolating the root cause.

Sensor Mount Design

Designed a laser-cut riser to relocate the ultrasonic sensor above the RedBoard without blocking port access. Evaluated three solutions using Kepner-Tregoe Decision Analysis, designed the winner in AutoCAD, and assembled it with adhesive.

Maze Design & Fabrication

Designed the Challenge 4 modular maze with 45-degree angled walls — the highest difficulty score in the class. Cut all walls to AutoCAD specs and assembled with 3D-printed connectors.

Documentation

Led all project documentation: meeting minutes, testing notes, photo/video records, and the engineering design notebook. Received positive peer review for thoroughness and detail.

Results

Outcome

The robot completed all four challenges across the semester. The team's maze was among the most difficult in the class, and the navigation algorithm built to handle its 45-degree walls generalized effectively to all three Challenge 4 mazes. The engineering design notebook received positive peer feedback for its thoroughness and organization.

Documentation

Design Notebook

The full engineering design notebook for this project — covering every meeting, design decision, test result, and reflection across all four challenges.